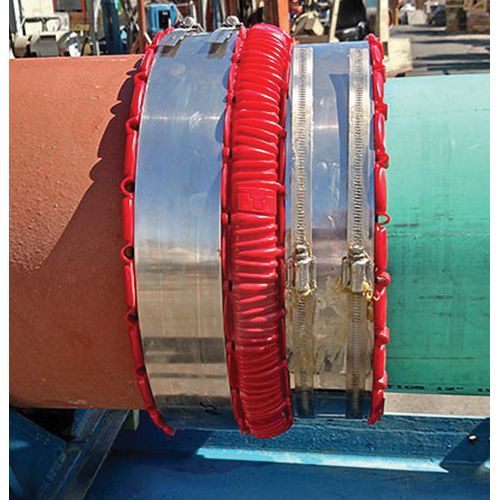

Robust, compact repair coupling for most types and sizes of gravity flow, non-pressure sewer/drainage pipes. One coupling per nominal diameter joins clay, ductile iron, asbestos cement, cast iron and plastic.

MAXADAPTOR® Universal Sewer Repair Coupling, 5 in Fitting, 1000 psi Tensile Strength, Elongation: 200 %, 80 in-lb Torque, Suitable For Use With: Clay, Ductile Iron, Asbestos Cement, Cast Iron and Plastic Gravity Flow and Non-Pressure Sewer/Drainage Pipes, 304 Stainless Steel

| Elongation | : | 200 % |

| Fitting Size | : | 5 in |

| Material | : | 304 Stainless Steel |

| Suitable For Use With | : | Clay, Ductile Iron, Asbestos Cement, Cast Iron and Plastic Gravity Flow and Non-Pressure Sewer/Drainage Pipes |

| Tensile Strength | : | 1000 psi |

| Torque Rating | : | 80 in-lb |

- AISI 304 Series stainless steel Click-Lock clamping system and high-impact polyamide (nylon) securing cage ensure shear load stabilization and a precision-fit on any pipe, watertight, leak-proof seal resists infiltration and exfiltration

- AISI 304 Series stainless steel components resist corrosion in marine applications, poorly aerated/moist soils, contaminated grounds conditions (e.g. industrial fill sites) and chloride, sulfates or bicarbonates in ground water

- EPDM synthetic rubber sealing gasket resists ultraviolet rays, ozone, fungus growth, natural soil erosive properties and normal sewer gases

- EPDM rubber permit a substantial degree of distortion without change in basic physical resistance, more pliable and easier to install in cold weather applications than elastomeric PVC gaskets

- Internal pipe stop for precise installation, reduces noise and vibration

- AISI 304 Series stainless steel Click-Lock clamping system and high-impact polyamide (nylon) securing cage control load bearing between coupling and pipe surface, opposing shear forces and deflection, while maintaining pipe alignment and flexibility

- Installs with a pre-set cordless drill calibrated to 80 in/lb

Instruction/Installation Manual

Instruction/Installation Manual Video Link

Video Link